SK series ultra high speed metal circular saw

Multiple technological innovations

leading industry level

Under the innovation of R & D center, the new super high speed SKseries high-speed metal circular saw machine has realized a number of technical innovation, making s series metal circular saw machine technology leading the industry level. From the automatic feeding system to the tailless device of the front clamp vise to the horizontal feed sawing mode, the saw blade clamping system, the oil mist collection device, the optical fiber servo electronic control system and other links have been innovated, which makes the S series metal circular saw have higher cost performance ratio, more efficient cutting speed, more energy saving and more environmental protection.

SK series metal circular sawing machine's high and new technology, such as fast, province, stability, precision, fusion and specialty, has become a new favorite of the industry. In 2015 and 2016, jingweite company was selected as "excellent forging equipment supplier" by China Forging Association, and sa-150 developed by jingweite company was awarded as "key recommended product of advanced forging auxiliary equipment".

SK series metal circular saw is favored by famous domestic enterprises such as Chang'an Automobile, BYD automobile, star group, Yuejin forging, triple forging, ocean precision forging, etc., and also exported to Turkey, Belarus, South Korea, India and other countries.

SZpecial circular saw for stainless steel

Specially designed for cutting difficult materials

to improve the overall rigidity of machine tool

Based on the s series high-speed metal circular saw platform, it is specially designed for cutting stainless steel and other difficult materials. In addition to maintaining the advantages of the original circular saw, the overall rigidity of the machine tool is improved, and the service life of the saw blade is significantly improved.

SA series ultra high speed metal circular saw

Based on the platform of S series ultra-high speed metal circular sawing machine, Jingweite Company has launched more economical SA series products, and the SA-150 developed by Jingweite Company has won the "Key Recommended Product of Advanced Forging Auxiliary Equipment" of China Forging Association.

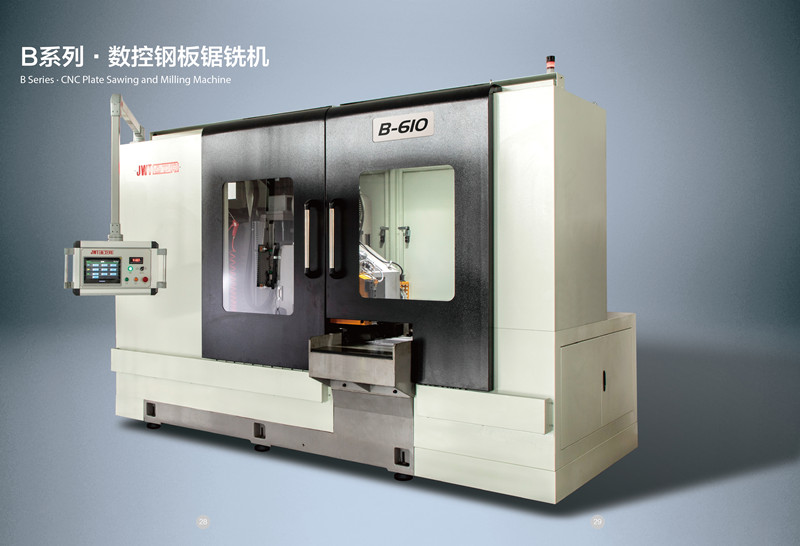

Numerical control steel plate sawing and milling machine

At present, CNC steel plate sawing and milling machine tool is in the monopoly state abroad, and it is still in the early stage of research and development in China. With the efforts of Jingwei people for many years, he took the lead in developing CNC steel plate sawing and milling machine tools, filling the gap of domestic steel plate circular saw efficient and accurate sawing and milling, and its performance reached the international level. Products can be widely used in metallurgy, machinery, mold manufacturing and other industries, compared with the traditional band sawing machine, with sawing speed, high precision, excellent section characteristics. Numerical control steel plate sawing and milling machine adopts fixed beam gantry frame structure, which is convenient for steel plate feeding and discharging, and the cutting length of steel plate is not limited by the machine structure.

The numerical control steel plate sawing and milling machine is composed of the cutting movement of circular saw blade, the vertical and horizontal feeding movement of gear box and the feeding and discharging movement of steel plate. The movement adopts the numerical control system to control the servo motor to realize the stepless speed change; The cutting speed and the feeding speed are adjusted according to the material property and the thickness of the sawing steel plate; Adjust the length according to the need of sawing. The processed product has high dimensional precision, and the flatness, the verticality and the roughness of the sawing surface are better.

The feeding direction and the cutting direction of the steel plate are clamped synchronously in the cutting process, and a special vertical lifting structure is designed to prevent the saw blade from rubbing with the surface of a sawing material when retracting, so that the service life of the saw blade is prolonged, and meanwhile, the positioning precision and the cutting stability and reliability are ensured; The machine tool adopts oil mist micro-lubrication cooling mode, which is clean and environmentally friendly. Because of the edge on the side of the cutter, the sawing surface has the characteristics of milling surface.

Blanking automatic production line

Specialization and matching

With the continuous improvement of forging requirements in the forging industry, the original production conditions, equipment and equipment, process requirements, accuracy requirements, etc. should also be changed and improved accordingly. Most enterprises will realize the transition from conventional forging to precision forging, and their conventional production mode must be changed into intelligent, matching and wired production mode to meet the high-speed development of enterprises In order to meet the needs of the exhibition, Jingwei special personnel will grasp the blanking process of the important process link in the forging industry, and make significant improvement and upgrading to create a blanking automation production line.

- TYPE

- Actual case